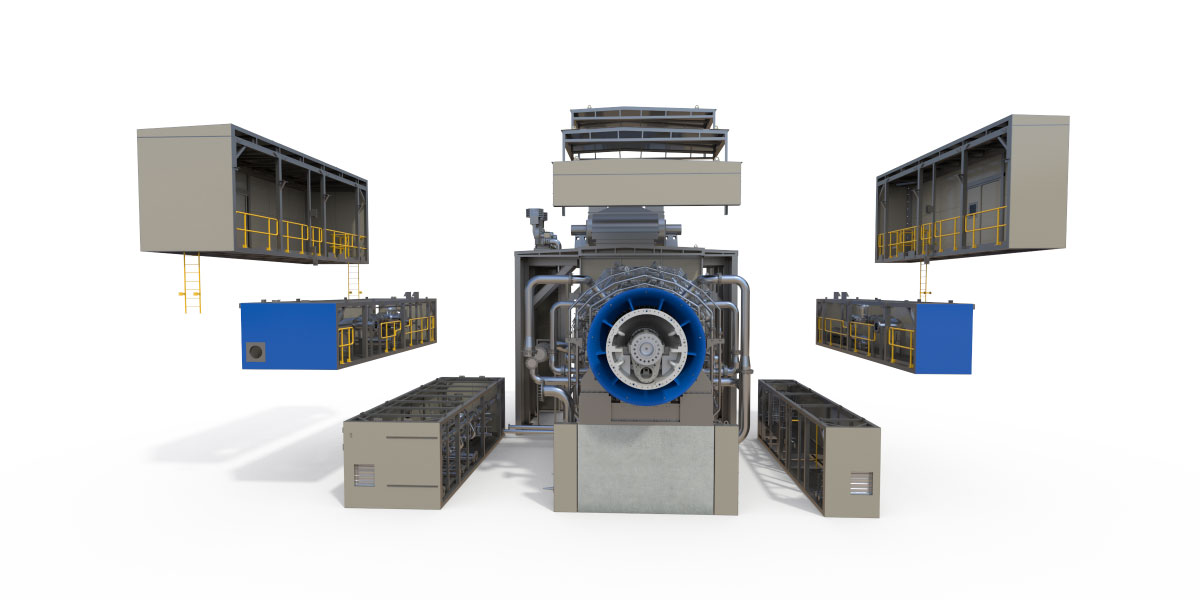

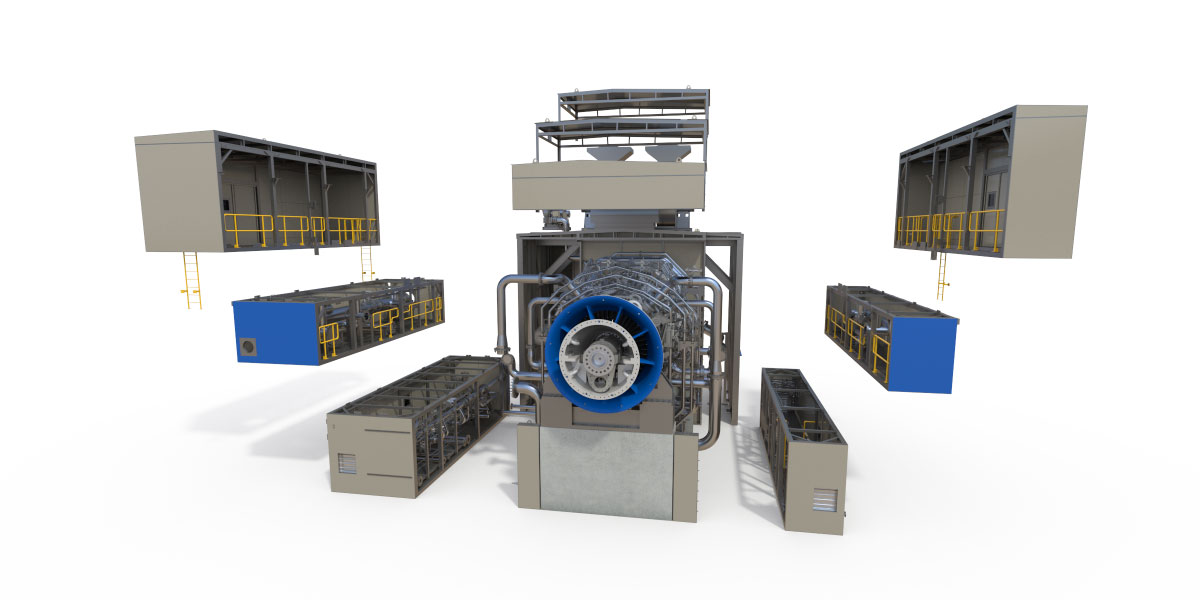

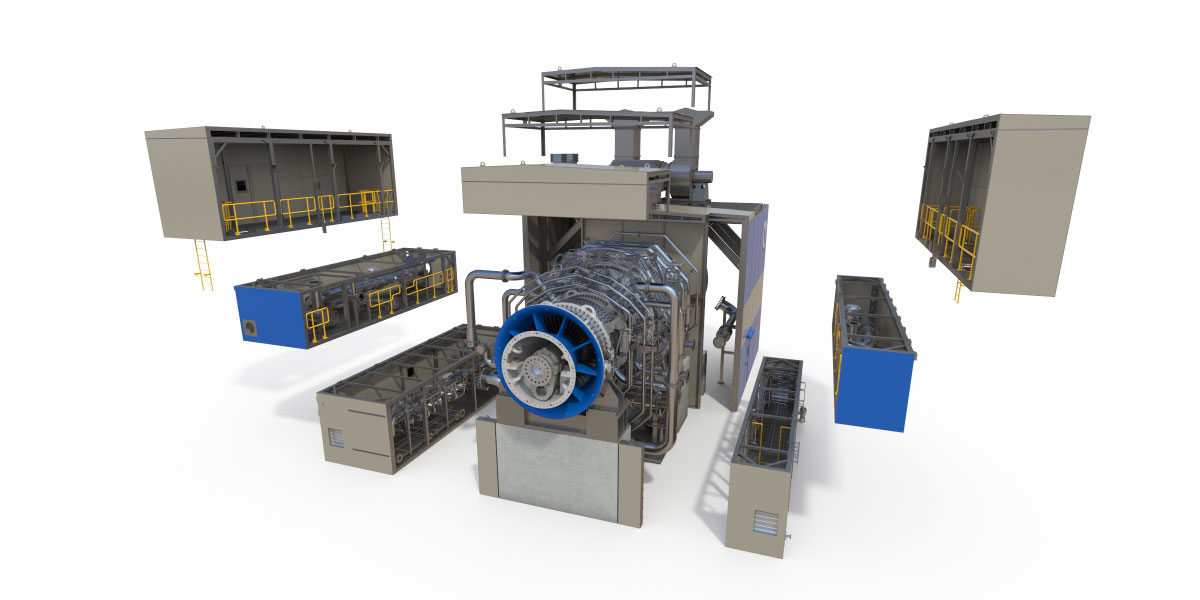

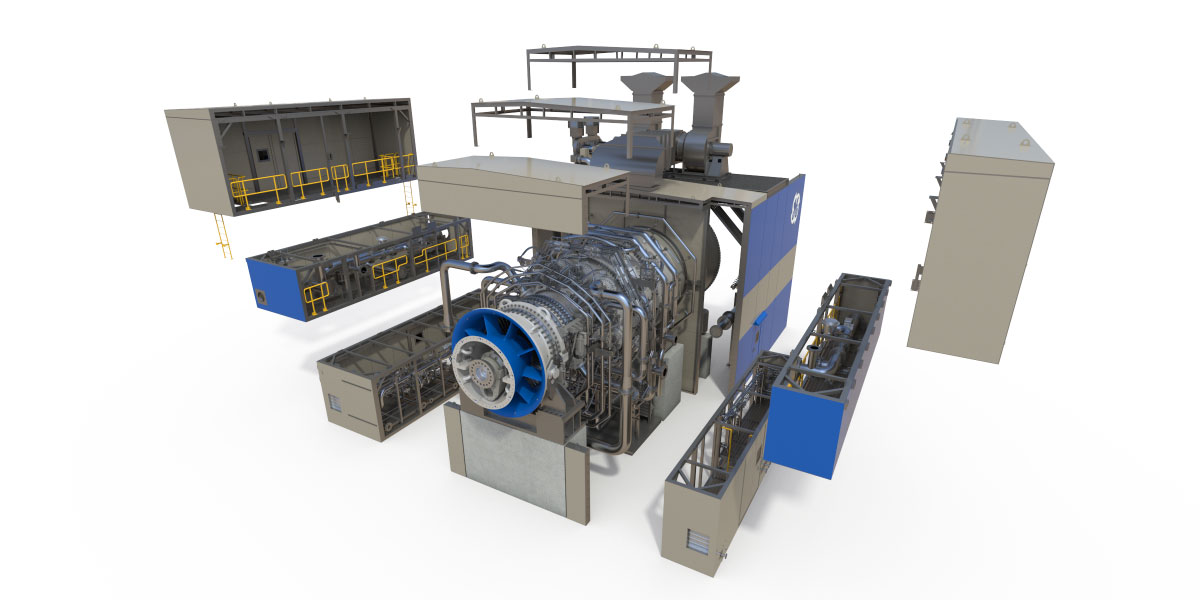

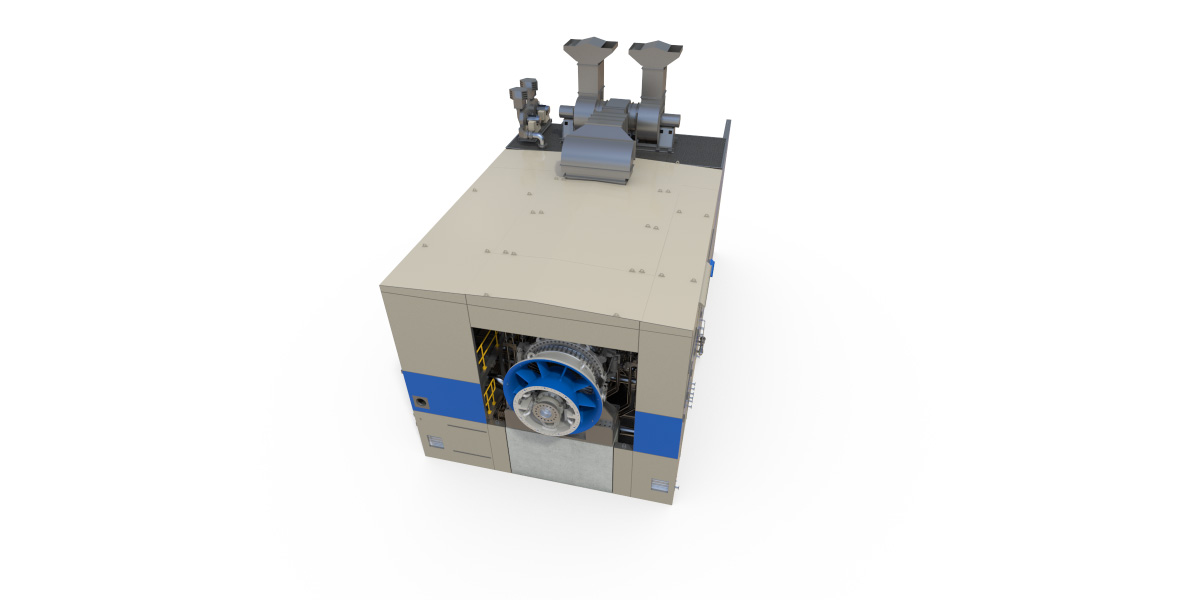

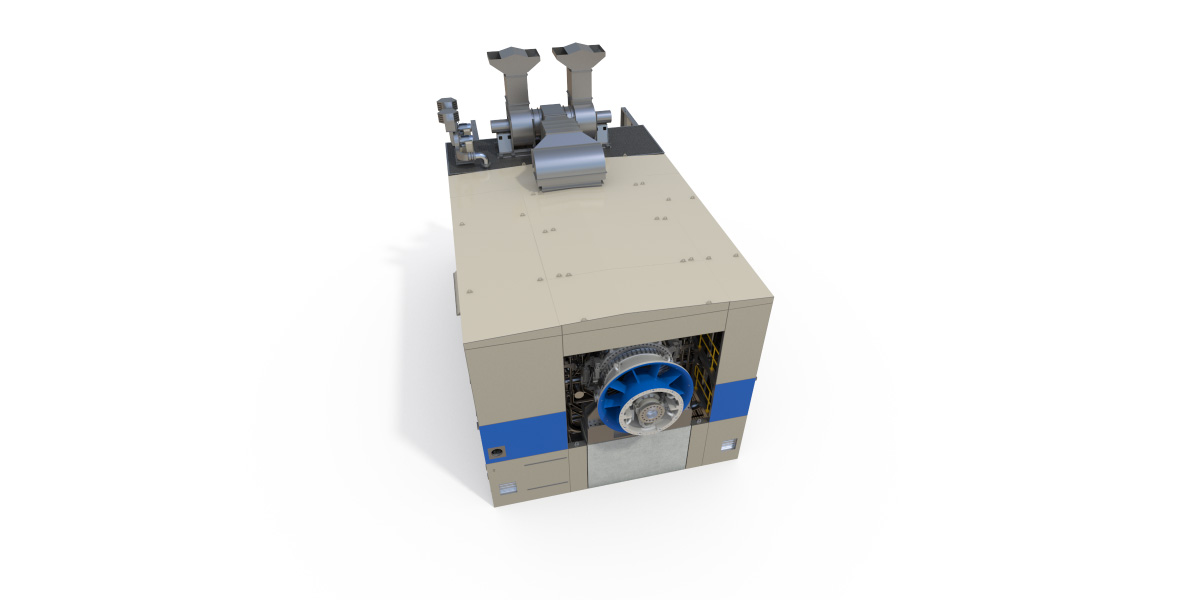

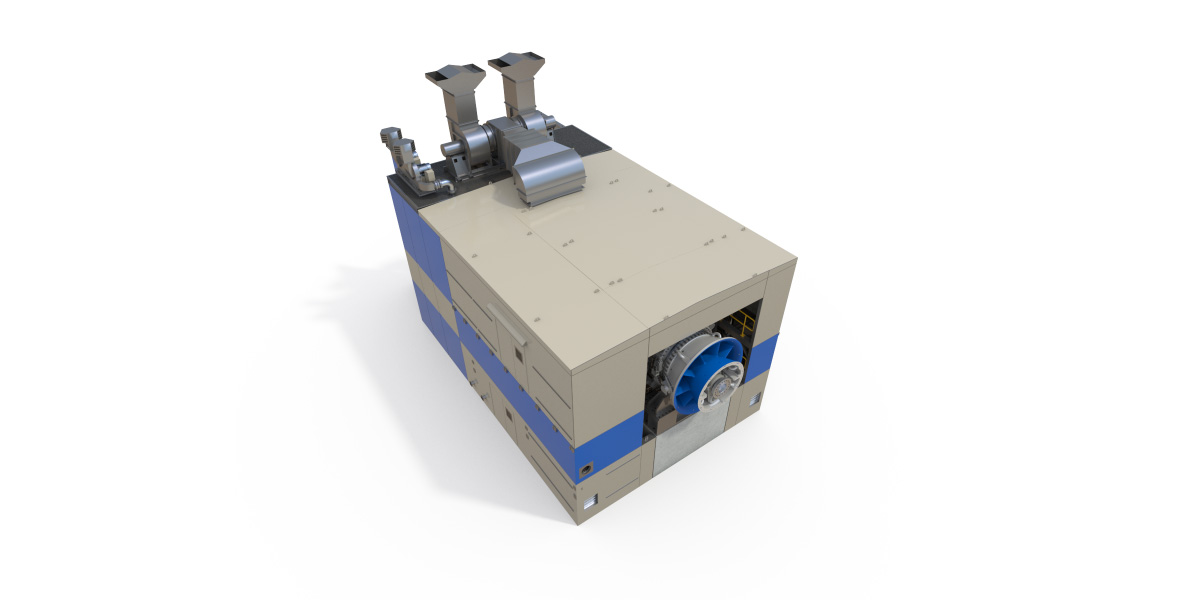

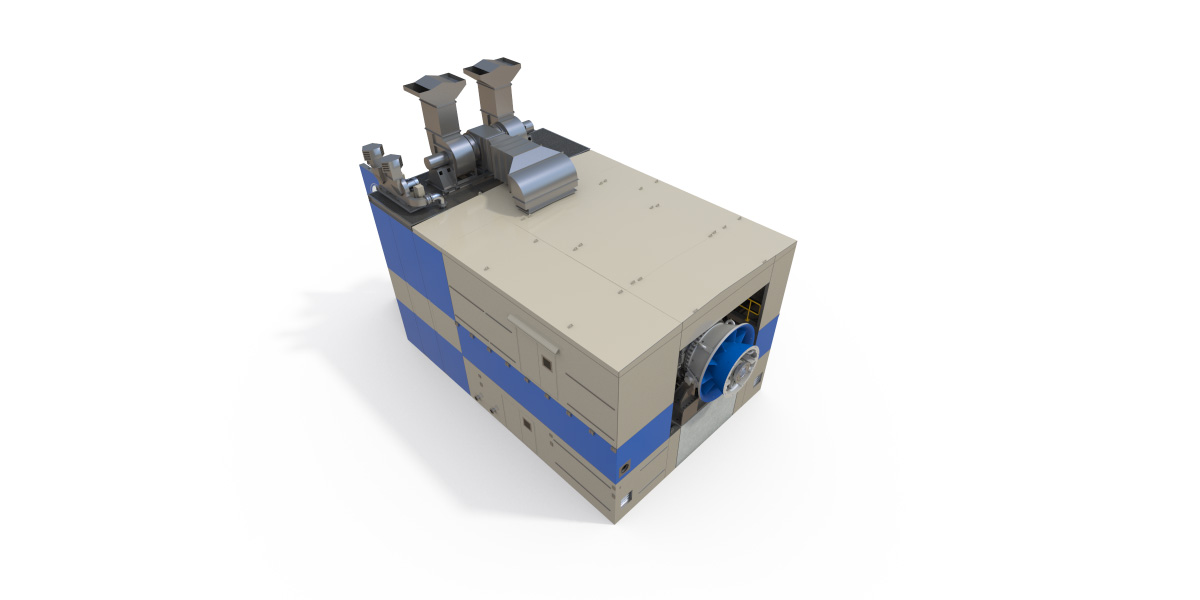

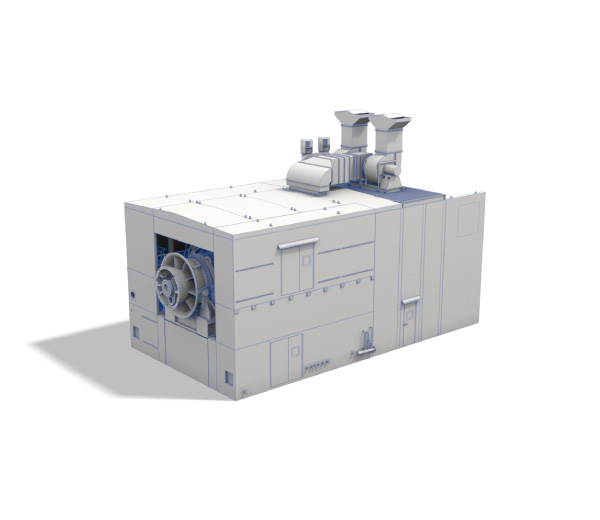

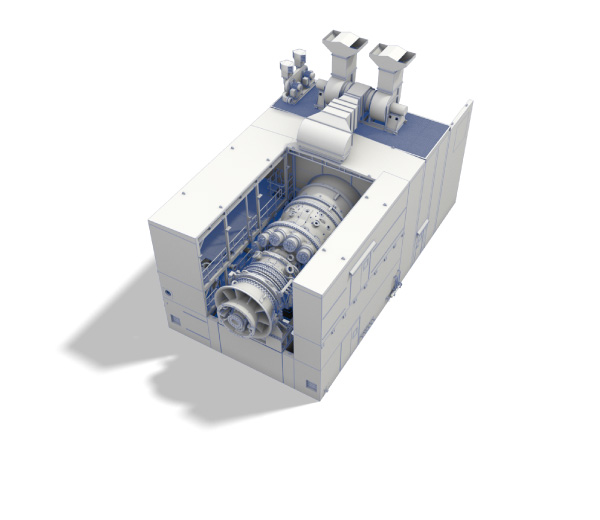

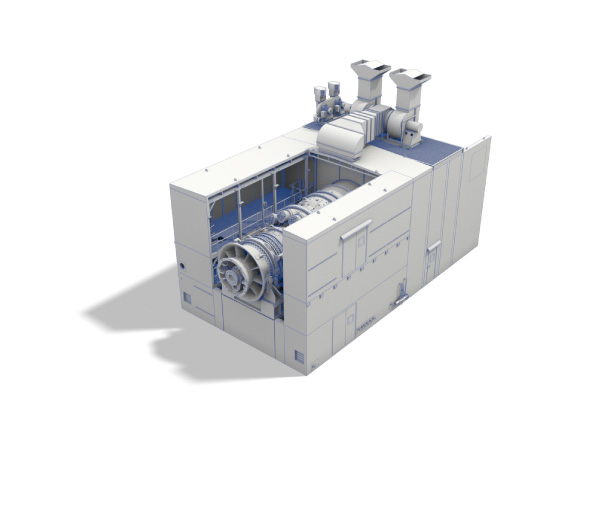

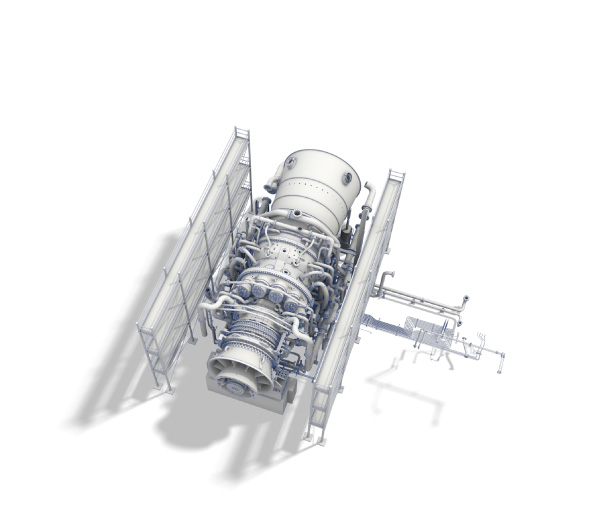

HA Gas Turbine Enclosure

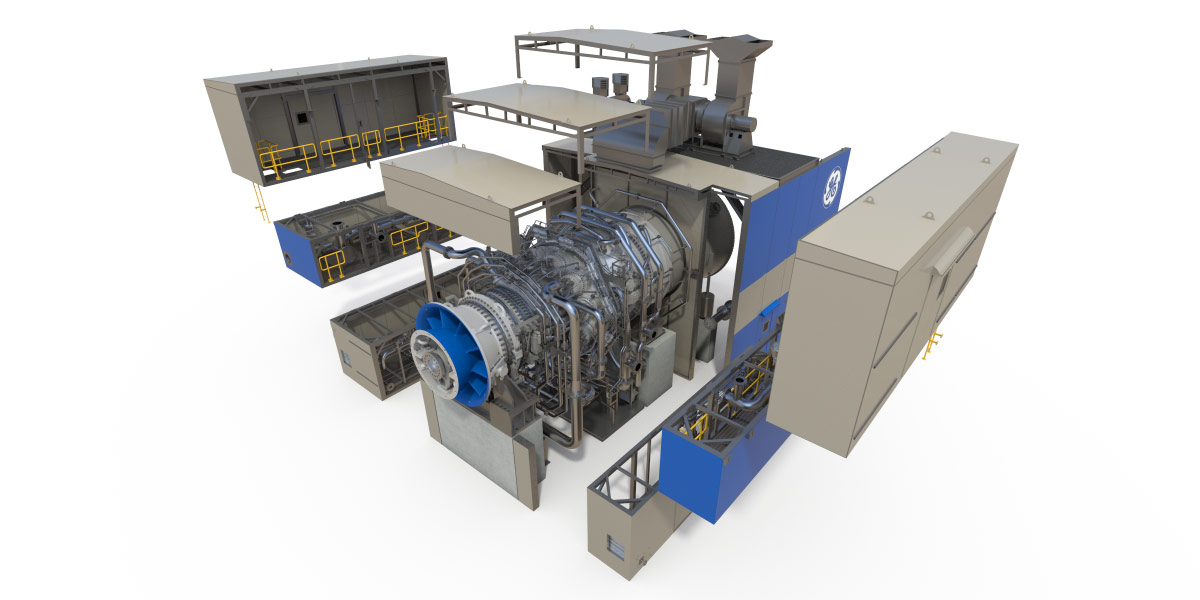

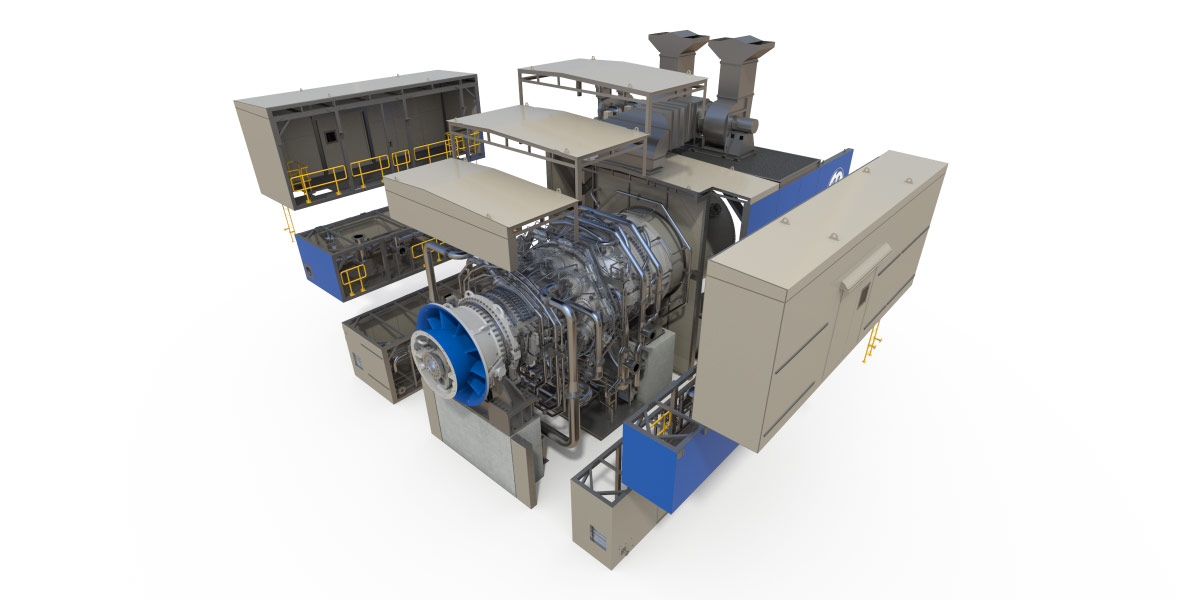

The new HA Gas Turbine enclosure improves upon its previous design by incorporating a module-based structure, enabling quicker and easier installation and maintenance.

The new HA Gas Turbine enclosure improves upon its previous design by incorporating a module-based structure, enabling quicker and easier installation and maintenance.

The new HA Gas Turbine enclosure improves upon its previous design by incorporating a module-based structure, enabling quicker and easier installation and maintenance.

less skill needed in the trades

*compared to 7F gas turbine

greater equipment accessibility affords simpler, faster serviceability

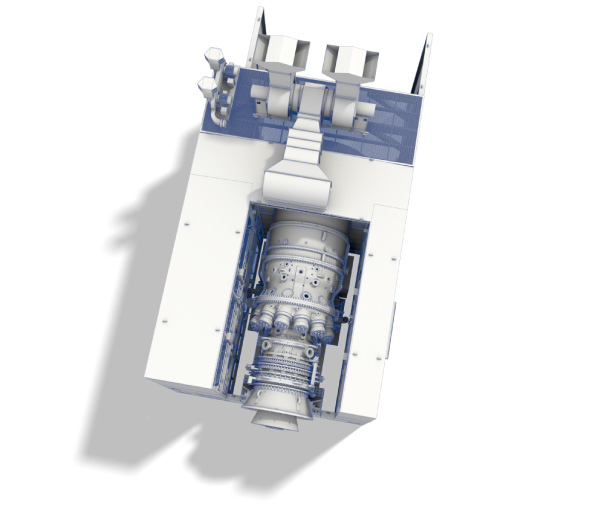

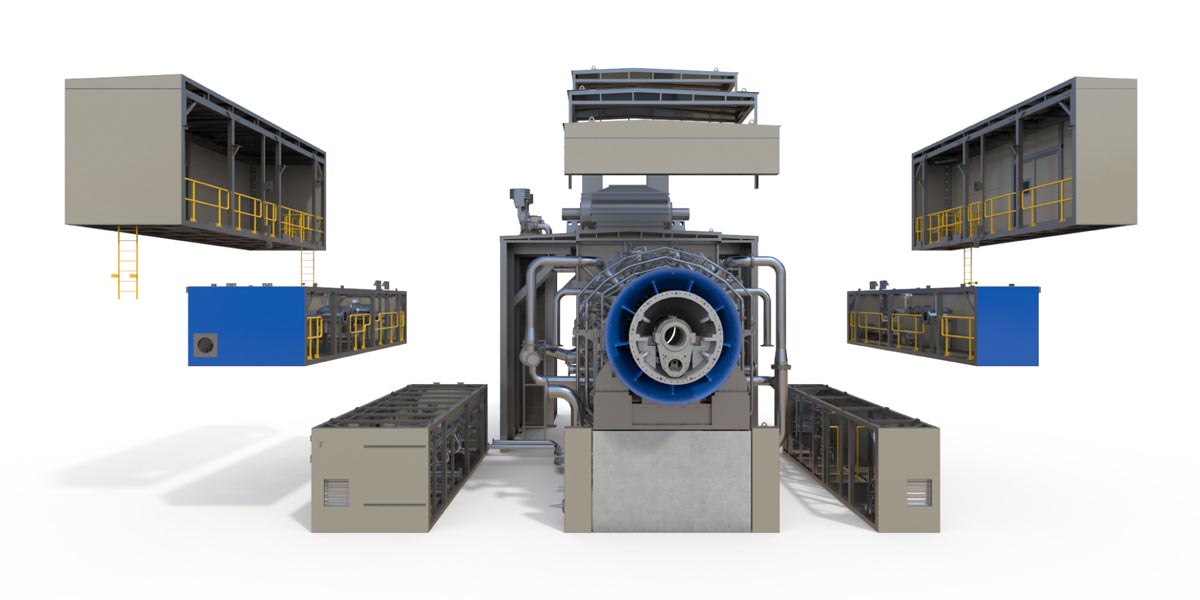

Upper Enclosure(Service Platform)

Upper Enclosure(Service Platform)

Air Extraction Module

Air Extraction Module

Fuel Control Module

GT Drains Module

Lower Air Extraction Module

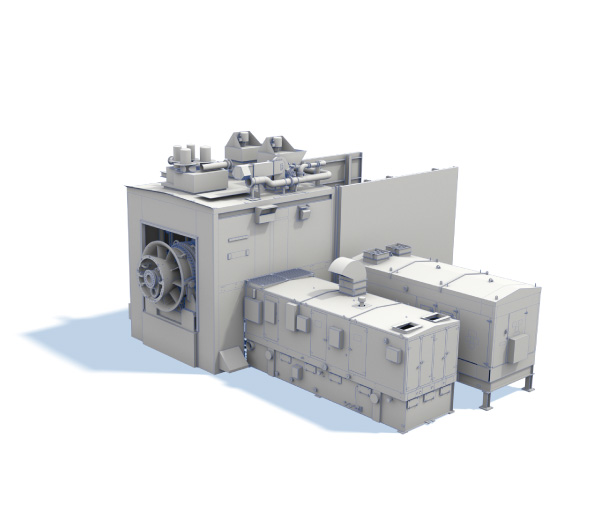

HA modularity significantly reduces required lay down space and logistics time needed to locate and transport field installed piping and valves

HA Enclosure modules and valves

installed in approximately 7 weeks

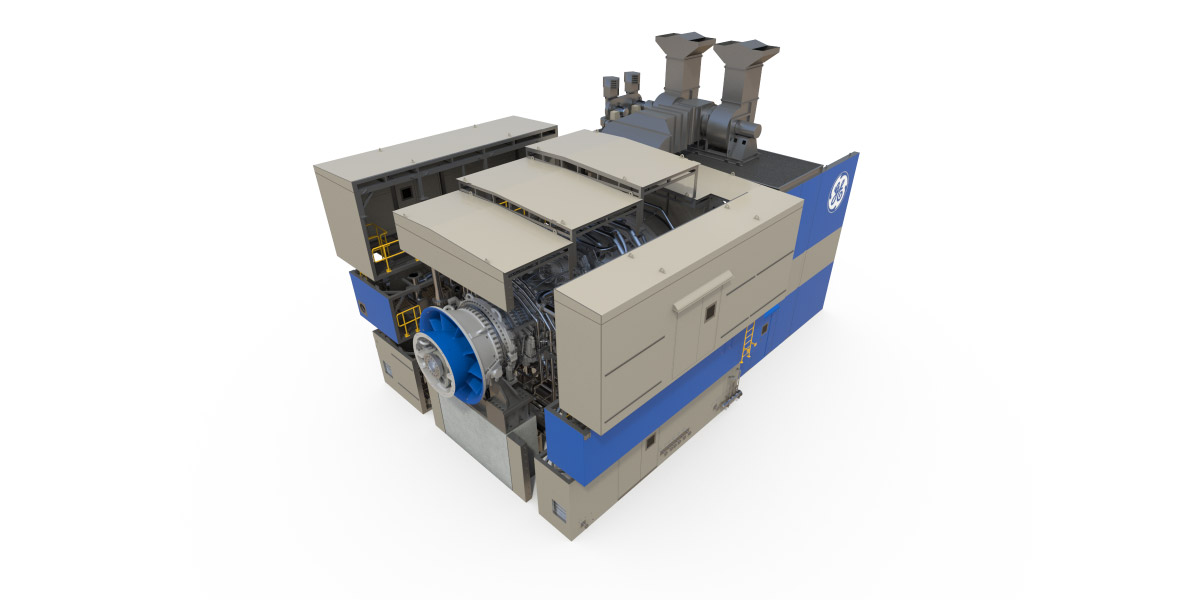

Segregated work zones allow for:

First Fire ready in 10,000 fewer hours

*compared to 7F enclosure

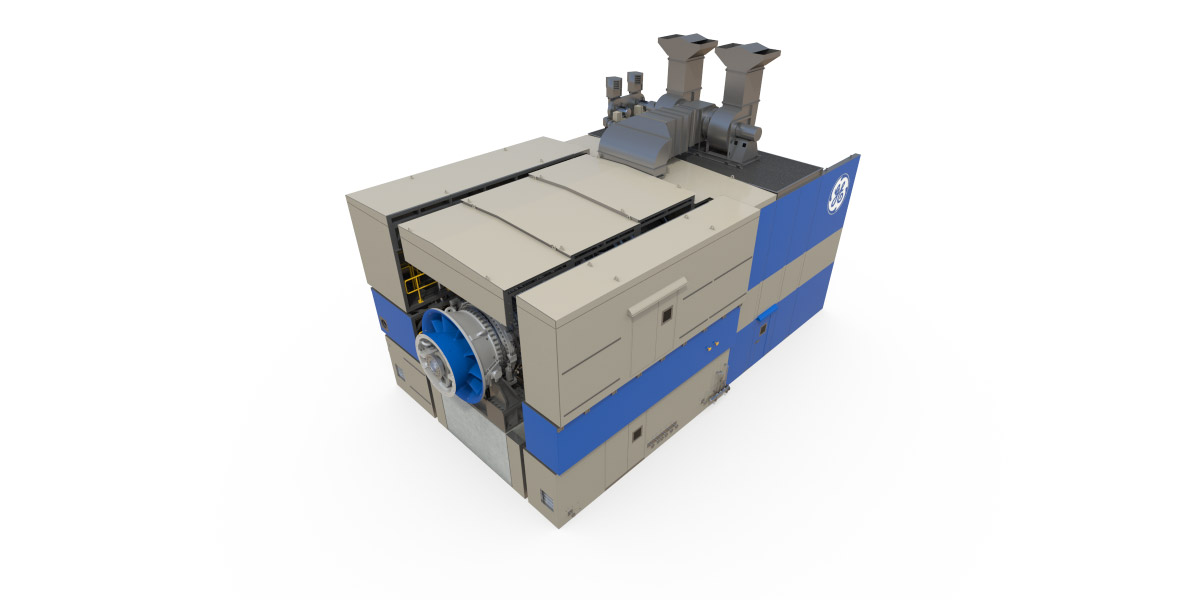

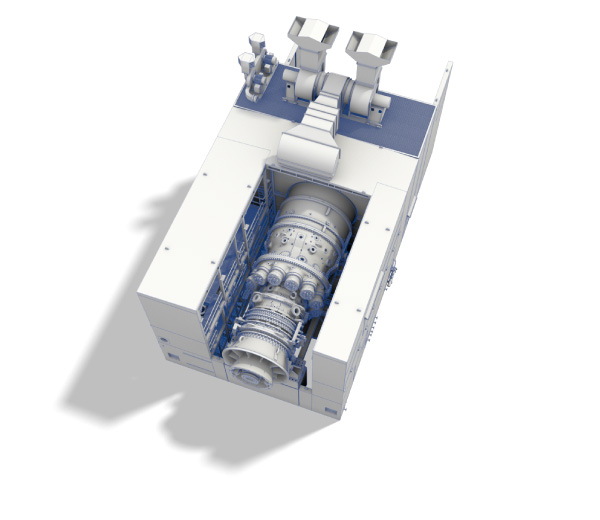

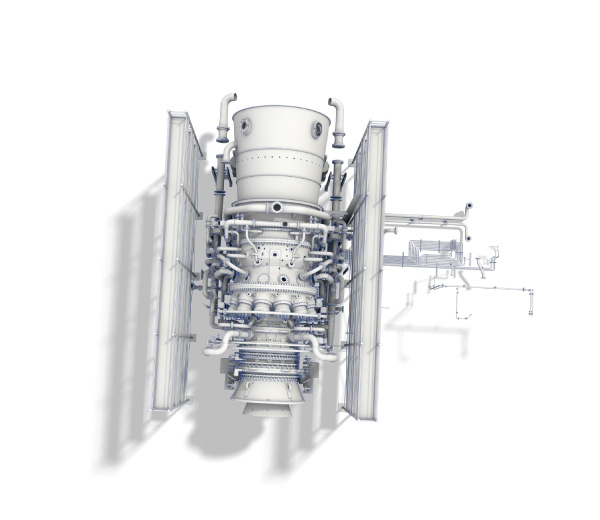

7HA ENCLOSURE VOLUME

27,100 [ft³]

7F ENCLOSURE VOLUME

13,800 [ft³]

major inspection (front)

major inspection (front)

combustion inspection (middle)

hot gas path inspection (rear)

sloped inlet allows for lower crane and building height

rotor-removal clearance

single ventilation extraction (no removal required)

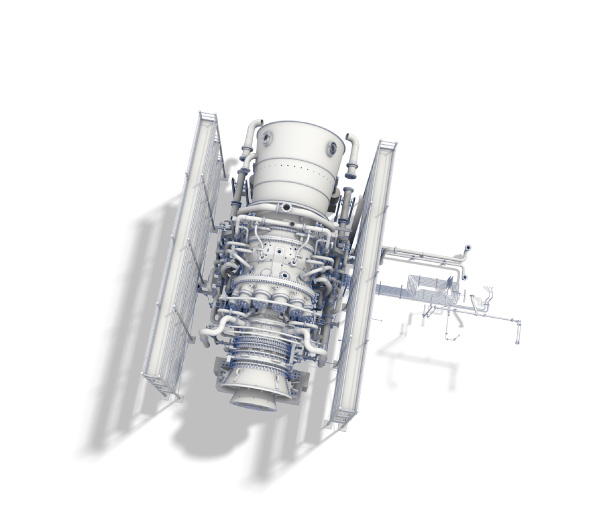

98%

REDUCTION IN FIELD-INSTALLED VALVES

54%

REDUCTION IN TURBINE FIELD WELDS

50494847464544434241%

REDUCTION IN ELECTRICAL TERMINATIONS REDUCTION IN PIPING SYSTEM INTERFACES

* all comparisons based on 7F.03 Gas Turbine

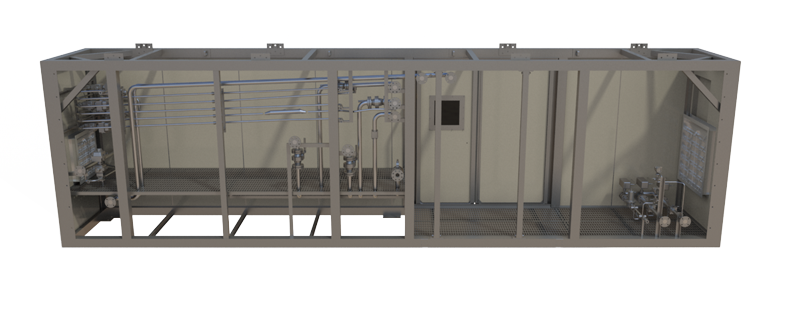

simplified interface points

Integrated cable trays replace field-installed conduit Nearly 50% reduction in number of Junction Boxes Nearly 70% reduction in number of field terminations